An air release valve plays a critical role in fluid systems. Engineers rely on these valves to prevent air accumulation in pipelines. "Air release valves are essential for maintaining system efficiency," states Dr. James Thompson, a leading expert in fluid dynamics. His insight highlights the importance of understanding how these valves function.

Air release valves automatically release trapped air from pipelines as fluid flows. This prevents vapor locks and reduces pressure fluctuations. Systems without proper air release valves can face failures. The risk of blockages can lead to severe efficiency drops. Many operators underestimate the complexity of these devices.

Understanding the mechanics of an air release valve is not always straightforward. Design flaws or improper installations can hinder performance. Thoughtful consideration and regular maintenance can enhance reliability. There’s much to ponder about air release valves before implementing them in any system.

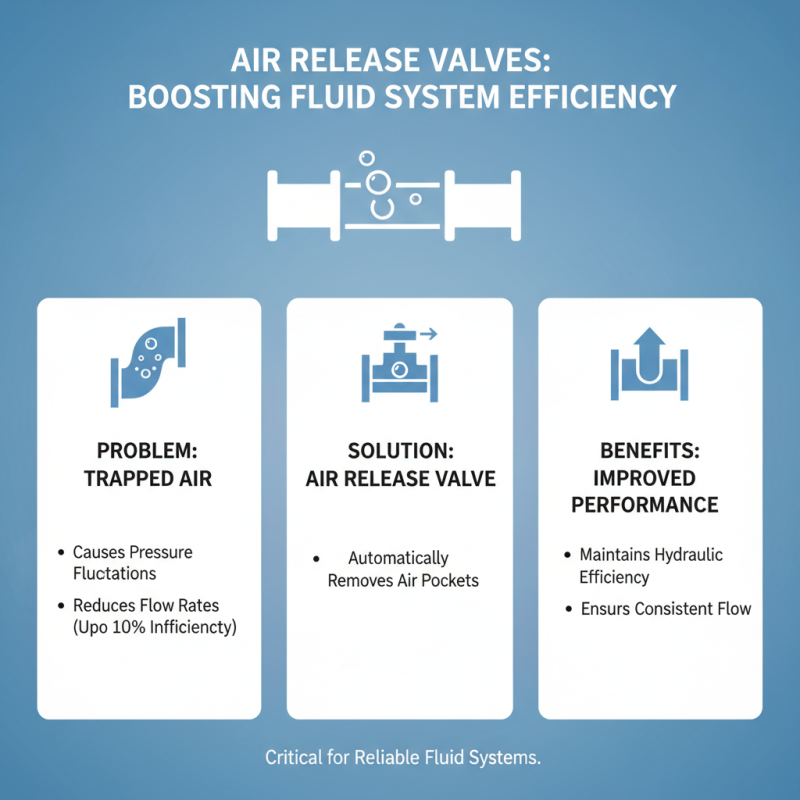

An air release valve is an essential component in fluid systems. It prevents air accumulation. Air buildup in pipelines can cause pressure fluctuations that lead to system inefficiencies. According to industry reports, maintaining optimal pressure levels is crucial for system performance.

These valves allow trapped air to escape from pipelines. This process helps maintain steady fluid flow. Without an air release valve, systems may suffer from water hammer effects, which can damage pipes. A study by the Water Research Foundation states that over 40% of pipeline failures stem from air-related issues. Such statistics highlight the importance of these valves.

However, not all air release valves function effectively. Some may clog or fail to open. Regular maintenance is vital. An overlooked valve can lead to costly repairs. Ensuring proper installation and regular checks is necessary. In an efficient system, the air release valve plays a key role in sustaining performance and longevity.

Air release valves play a critical role in fluid systems. They help maintain hydraulic efficiency by removing trapped air. When air accumulates in pipelines, it can cause pressure fluctuations and reduced flow rates. According to industry reports, up to 10% of system inefficiencies stem from air pockets. This is where air release valves come in.

These valves operate using a simple mechanism. As fluid flows through a pipeline, air is pushed toward the valve. When the internal pressure exceeds a set point, the valve opens. This allows accumulated air to escape, while minimizing fluid loss. When fluid levels drop, the valve automatically shuts. However, valves can fail if not maintained. Regular inspections are necessary to ensure proper function.

The choice of materials affects valve performance. Corrosive environments can degrade valve seals over time. In fact, studies indicate that nearly 15% of failures relate to material fatigue. Operators must consider environmental factors when selecting valves. Designing for longevity can prevent unexpected downtime.

Air release valves are essential components in fluid systems. They allow trapped air to escape from pipelines. This helps maintain optimal flow and prevent pressure buildup. In many cases, air can cause hydraulic shocks or water hammer. Such issues can lead to costly damage and system failures.

Key components of air release valves include the valve body, float, and discharge orifices. The valve body houses the mechanism. It is usually made of robust materials to withstand internal pressures. The float rises and falls with the water level. When air collects, the float drops, opening the orifice and releasing trapped air. Research indicates that properly functioning air release valves can increase system efficiency by 15-20%.

However, not all air release valves perform as expected. Maintenance issues are common. Accumulated debris can block orifices, leading to valve failure. According to data from industry studies, about 25% of air release valves experience performance issues due to corrosion or scaling. Regular inspections and maintenance are crucial to ensure reliability. A neglected air release valve may cause significant problems, underscoring the need for a proactive approach.

Air release valves play a crucial role in water systems and wastewater management. They help release trapped air that accumulates in pipelines. When air is not vented, it can create pressure fluctuations and even damage pipes. According to a 2021 industry report by the American Water Works Association, about 15% of water loss can be attributed to air pockets in systems.

In wastewater management, these valves prevent sediment buildup. When air accumulates, it disrupts flow, leading to blockages. A study indicated that over 20% of wastewater systems experience inefficiencies due to such blockages. Proper installation of air release valves can significantly reduce maintenance costs and enhance overall system efficiency.

However, improper valve selection or installation may lead to issues. Some valves may not open effectively under specific pressure conditions. Regular inspections are vital. They ensure that valves function correctly. An underperforming valve can turn a minor issue into a major problem, costing thousands in repairs. The importance of air release valves cannot be overstated, yet they are often overlooked in initial design stages.

Air release valves play a crucial role in various industries, ensuring efficient operation of fluid systems. These valves help manage trapped air in pipelines, preventing pressure build-up and protecting the integrity of the system. Regulations and industry standards dictate their usage, focusing on safety and reliability.

In many regions, standards such as ISO and API outline the design and installation criteria for air release valves. Compliance with these guidelines is essential to meet safety requirements and enhance performance. Each valve should be regularly inspected and maintained, as neglect can lead to failures.

Tips: Always check local regulations. They may differ significantly. Install air release valves at high points in your pipeline for optimal performance. Regular training on valve operations can prevent accidents. Identifying issues early helps avoid costly repairs later. Prioritize equipment reliability to maintain operational efficiency.