In today's industrial landscape, the importance of selecting the right pressure reducing valve (PRV) cannot be overstated. According to a report by the International Society of Automation, a significant 30% of energy costs in manufacturing processes can be attributed to inefficient pressure management. Properly implemented PRVs not only optimize these costs but also enhance system safety by preventing overpressure situations. Furthermore, a study from Frost & Sullivan indicates that the global market for PRVs is projected to grow at a CAGR of 5.4% by 2025, underscoring their critical role in fluid control systems. As businesses seek to improve operational efficiency and comply with safety regulations, understanding the nuances of selecting the right pressure reducing valve becomes essential for maximizing system performance and minimizing risks.

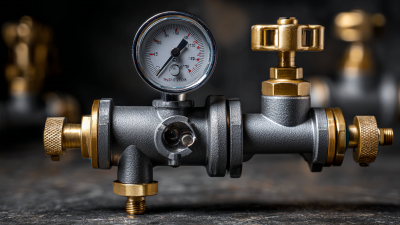

When selecting a pressure reducing valve (PRV), understanding your system's pressure requirements is crucial. Every system operates under specific pressure conditions, which can significantly impact the performance and longevity of the equipment. Start by determining the operating pressure range of your system, as this will guide you in choosing a valve that maintains optimal performance while protecting components from potential damage caused by excessive pressure.

When selecting a pressure reducing valve (PRV), understanding your system's pressure requirements is crucial. Every system operates under specific pressure conditions, which can significantly impact the performance and longevity of the equipment. Start by determining the operating pressure range of your system, as this will guide you in choosing a valve that maintains optimal performance while protecting components from potential damage caused by excessive pressure.

Next, consider the inlet and outlet pressure requirements. The valve must be capable of reducing the incoming pressure to a designated outlet level that your system can handle. Additionally, evaluate any pressure fluctuations within the system, which can occur due to varying demand or other operational dynamics. Selecting a PRV that can respond effectively to these changes is essential for maintaining system stability and efficiency. Ultimately, aligning the valve specifications with your system's pressure requirements leads to enhanced reliability and performance.

When selecting the ideal pressure reducing valve (PRV) for your system, it is essential to consider several key features that can significantly impact performance and efficiency. Firstly, the valve's pressure range is crucial; it must be designed to handle the specific pressure requirements of your application. This ensures optimal regulation without risking damage to the system or components. Additionally, look for valves equipped with adjustable set points, allowing for easy calibration to meet changing operational demands.

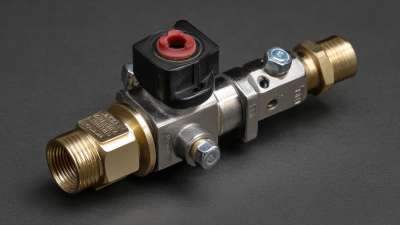

Another important feature to evaluate is the construction materials of the valve. Depending on the fluids involved and their temperatures, choosing a valve made from corrosion-resistant materials can prolong the life of the PRV and maintain its reliability. Furthermore, the valve's flow capacity is vital; it should accommodate the necessary flow rates without creating excessive pressure drops. Lastly, consider the ease of maintenance; valves designed for simple access and service will reduce downtime and maintenance costs, contributing to overall system efficiency.

Selecting the right size for a pressure reducing valve (PRV) is crucial for ensuring optimal performance in any system. A correctly sized PRV not only maintains desired pressure levels but also enhances the overall efficiency and longevity of the system. To begin with, understanding the flow requirements of your system is essential. This involves calculating the maximum and minimum flow rates, which will influence the valve's sizing. If the valve is too large, it may not be able to maintain the necessary pressure drop, leading to insufficient pressure regulation. Conversely, a valve that is too small may result in excessive pressure drops, causing operational issues and potential damage to system components.

In addition to flow rates, consider the specific application and the types of fluids involved. Different fluids have varying densities and viscosities, which can impact the performance of the PRV. Moreover, take into account factors such as temperature variations and installation location, as these can affect valve sizing as well. Proper sizing can be achieved by consulting manufacturer guidelines and utilizing sizing calculators that factor in these variables. By ensuring a well-matched PRV to your system's unique requirements, you can achieve reliable performance while minimizing maintenance needs and maximizing system efficiency.

| Valve Size (inches) | Flow Rate (GPM) | Pressure Drop (psi) | Material | Application |

|---|---|---|---|---|

| 1/2 | 10 | 5 | Brass | Residential Plumbing |

| 3/4 | 20 | 10 | Stainless Steel | Industrial Water Systems |

| 1 | 40 | 15 | PVC | Irrigation Systems |

| 1.5 | 75 | 25 | Bronze | Commercial HVAC Systems |

| 2 | 120 | 30 | Cast Iron | Fire Protection Systems |

When selecting a pressure reducing valve (PRV), the material composition plays a crucial role in ensuring longevity and efficiency. Common materials for PRVs include brass, stainless steel, and various plastics, each offering different benefits depending on the application. Brass is often favored for its excellent corrosion resistance and ability to handle moderate temperature ranges, making it suitable for water and low-pressure gas applications. Conversely, stainless steel provides superior durability and resistance to extreme temperatures and harsh chemicals, making it ideal for high-pressure environments or aggressive media.

Additionally, the compatibility of the valve materials with the fluid being controlled is a key consideration. For instance, while plastic materials can reduce weight and cost, they may not withstand high temperatures or certain corrosive substances. Therefore, it is essential to evaluate the specific conditions of your system—such as the temperature, pressure, and chemical composition of the fluids—before making a final decision. By prioritizing these material considerations, one can select a PRV that not only meets operational requirements but also enhances the overall efficiency and lifespan of the system.

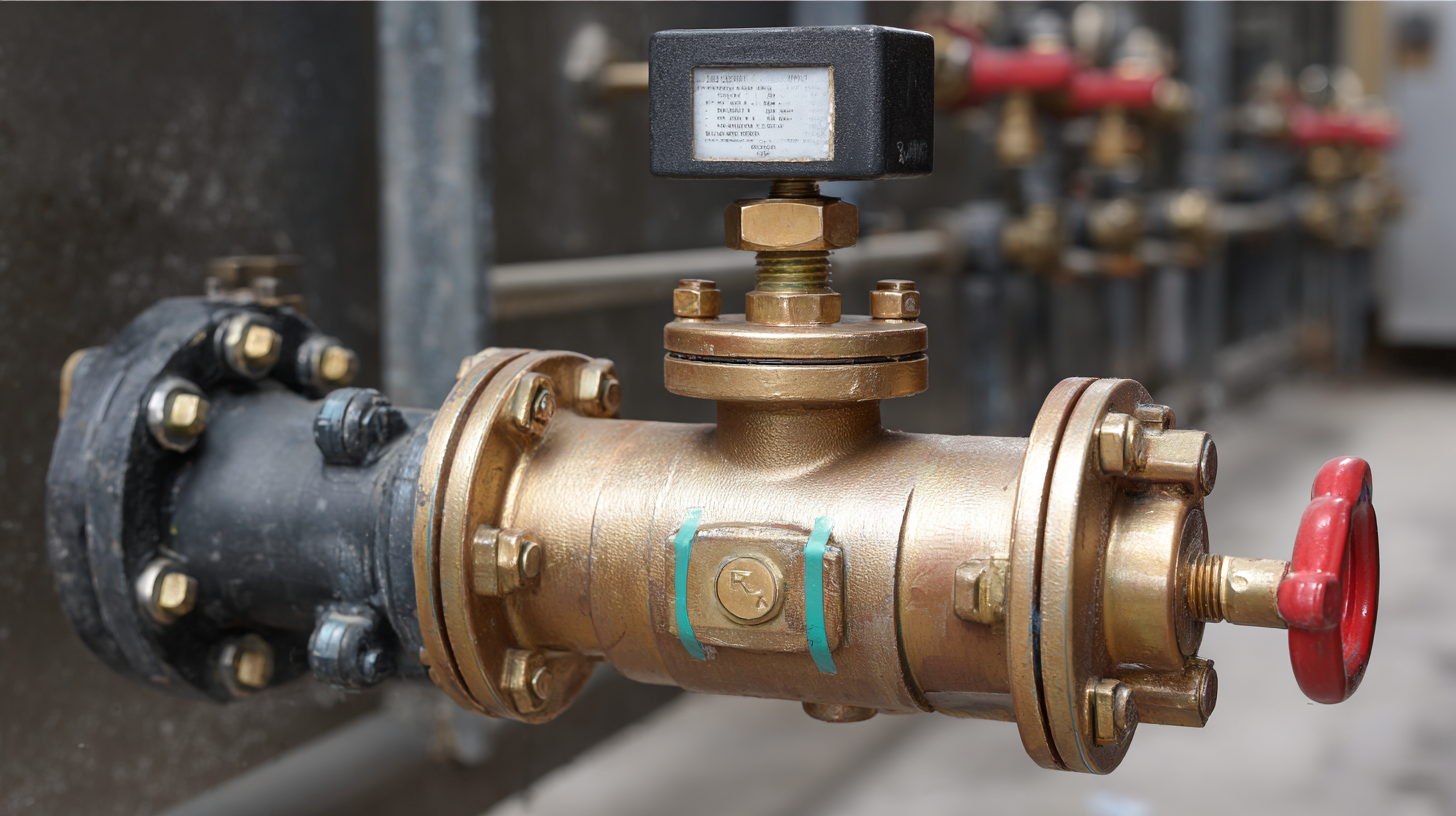

When selecting a pressure reducing valve (PRV) for your system, proper installation is critical for ensuring its peak operation. Common mistakes include improper placement and inadequate valve sizing, which can lead to inefficient system performance. According to industry reports, improper installation can reduce the efficiency of a system by up to 20%, impacting both operational costs and equipment longevity. Ensuring the PRV is installed in the correct orientation and location can significantly enhance its responsiveness and reduce wear over time.

Furthermore, neglecting to consider the flow rate and pressure requirements can lead to severe operational issues. Many systems are designed with specific flow characteristics, and failing to account for these interactions may result in fluctuations that compromise the entire operation. A recent survey highlighted that over 30% of systems face issues stemming from misconfigured valves. Regular maintenance and checks can prevent these pitfalls, keeping your pressure reducing valve functioning smoothly and efficiently throughout its lifespan. By taking heed of these common installation mistakes, you can ensure reliable performance and extend the longevity of your system.