Choosing the right 3 way valve for your plumbing needs may seem daunting. However, expert John Smith, a leader in the valve industry, reminds us, “Quality and application guide your choice.” A 3 way valve can direct flow in multiple paths, making it versatile. Its role is critical in various systems, from HVAC to water supply.

When selecting a 3 way valve, consider factors like function and compatibility. Different applications demand specific types. A valve suited for one purpose might fail in another. For instance, a simple home plumbing setup might not benefit from a high-end industrial option. Such mismatches can lead to unnecessary complications.

Reflect on your requirements before making a decision. Are you looking for durability, ease of installation, or cost-effectiveness? Remember, not all 3 way valves perform alike. Each one has unique characteristics and specifications. Investing time in understanding your needs will pay off. It’s easy to overlook details amidst product choices. Yet, finding the right valve can enhance your system’s efficiency significantly.

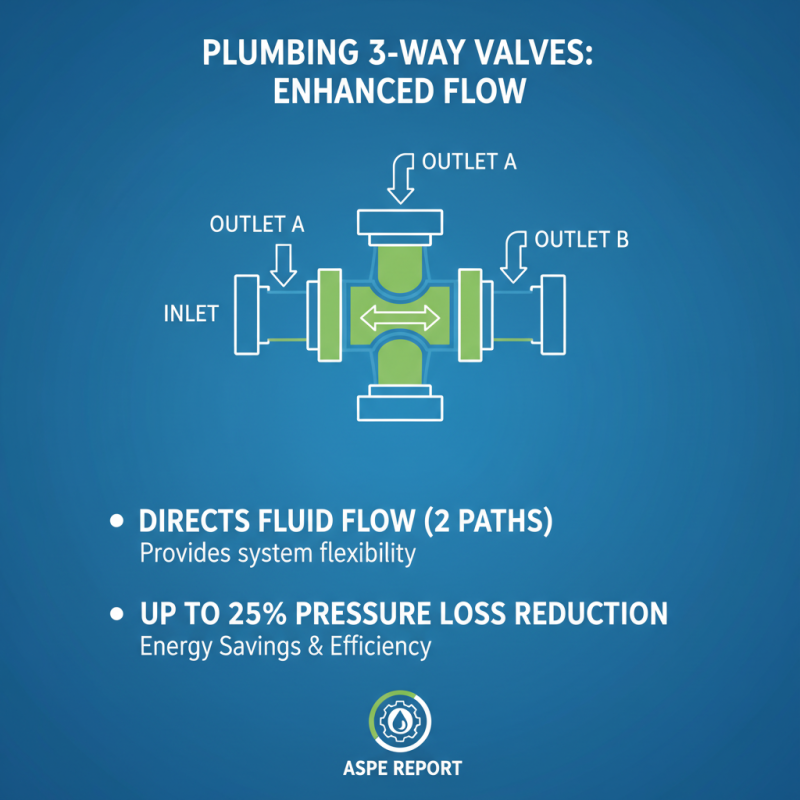

Understanding the functionality of 3-way valves in plumbing systems is crucial for effective plumbing design. These valves can route fluid flow in multiple directions, providing flexibility. According to a report by the American Society of Plumbing Engineers, properly installed 3-way valves can reduce system pressure losses by up to 25%. This can lead to significant energy savings.

When choosing a 3-way valve, consider its configuration. There are T-type and L-type configurations. T-type valves allow flow to be mixed or diverted. L-type valves redirect flow between two outlets. The right choice depends on your specific needs. For instance, T-type valves are ideal for applications where precise control of water mixing is necessary. However, improper selection can lead to inefficiencies.

Installation and maintenance matter too. A poorly installed valve can cause leaks and reduce system efficiency. Regular checks are vital to ensure valves function optimally. Some common issues include corrosion and wear. Addressing these proactively can avoid system failures. It’s essential to understand your plumbing system's requirements. Make informed choices to enhance performance.

When selecting a three-way valve, it's essential to know the different types available and their specific applications. A common type is the ball valve. It offers excellent flow control. This valve type is often used in heating systems and water distribution. Its simplicity in operation makes it a favorite among many plumbers.

Another type is the globe valve. This valve type is perfect for regulating flow. However, it can be a bit restrictive. Users often face challenges finding the right size for various pipes. Since globe valves require more force to operate, they may not be suitable for all situations.

Finally, consider the butterfly valve. This valve is lightweight and compact. It excels in applications requiring quick shut-off. However, improper installation can lead to leaks and operational issues. Choosing the right three-way valve can significantly influence your plumbing system's efficiency, but evaluating these options thoroughly is crucial.

| Valve Type | Application | Medium | Pressure Rating | Sealing Type |

|---|---|---|---|---|

| T-Port Valve | Mixing or diverting fluids | Water, Oil, Gas | 150 PSI | Soft Sealing |

| L-Port Valve | Diverting one flow path to another | Steam, Air | 300 PSI | Metal Sealing |

| Motorized 3 Way Valve | Automated control systems | Water, Coolants | 150 PSI | Soft Sealing |

| Manual 3 Way Valve | Manual flow control | Oil, Chemicals | 200 PSI | Metal Sealing |

Choosing the right 3-way valve can greatly impact your plumbing system. Evaluating key factors is crucial for making the best decision. Start by considering the flow direction. Some valves facilitate mixing, while others divert flow. Identify which function is essential for your needs. Each application may require a specific type of control.

Next, focus on the valve's material. Brass, PVC, and stainless steel are common options. The environment dictates the best choice. For instance, corrosive fluids need more durable materials. Additionally, think about the valve size. An incorrectly sized valve can lead to inefficiencies. Measure your piping carefully.

Lastly, consider the pressure rating. Valves must withstand the system's pressure to function properly. Underestimating this can lead to leaks and other issues. Regularly review your choices. Sometimes, the most evident option may not be the best. Consider consulting a plumbing professional to ensure your selection fits all criteria. A little research goes a long way in securing a reliable plumbing system.

When installing a 3 way valve, consider the configuration of your plumbing system. Ensure its orientation matches the flow direction. Misalignment can lead to inefficiency. Check for tight connections. Loose fittings can cause leaks over time. Use plumber's tape for extra sealing where needed.

It’s also important to choose the right materials. Depending on the water type and pressure, some valves might corrode faster. Inspect the valve's body. While a sturdy construction is essential, a heavy valve may complicate handling. Test the valve's operation before final installation. Sometimes, a valve may seem fine during installation but function poorly later.

Lastly, avoid rushing through the installation. Take time to measure and adjust as needed. Be mindful of your environment. Dust or debris can interfere with operation. Regular checks after installation can prevent major issues. Ignoring these details might lead to frustrating problems down the line.

Maintaining a 3-way valve is essential for its longevity. Regular inspections can prevent major issues. Check for leaks and ensure all connections are tight. Inspect the valve for any signs of wear, such as corrosion. Address any problems immediately to avoid more significant damage later.

Tips: Clean the valve routinely. This prevents buildup that can impair function. Use gentle cleaning solutions to avoid damage. Monitor the performance regularly. If you notice unusual noises or slow operation, inspect it right away. These could be signs that maintenance is needed.

Don’t forget lubrication. Proper lubrication can enhance performance. Use the recommended types to ensure the valve operates smoothly. However, too much lubricant can cause issues. Finding a balance is crucial. Pay attention to the manufacturer guidelines. It can help avoid common pitfalls. Regularly reviewing these tips will keep your 3-way valve working effectively.