The safety valve plays a crucial role in various industrial applications. It ensures equipment operates within safe pressure limits. By preventing overpressure, a safety valve protects both personnel and machinery. However, many users overlook optimal usage strategies.

Understanding how to effectively operate a safety valve is essential. Installation is key. The valve must be correctly sized and positioned for efficiency. Regular maintenance checks are vital to ensure functionality. Signs of wear and tear can go unnoticed. Ignoring these can lead to dangerous situations.

Optimal performance requires training and awareness. Users should know the valve specifications and pressure requirements. Ongoing education can help prevent costly mistakes. Sometimes, common practices may not align with safety standards. Reflecting on safety protocols can save lives and resources.

Safety valves play a critical role in various systems by preventing pressure buildup. They automatically release excess pressure, ensuring safe operation. Understanding how they function is key to optimizing performance. When a system's pressure exceeds a preset level, the safety valve opens. This action allows for the immediate release of fluids or gases. It protects equipment and personnel.

However, not all safety valves are created equal. Sometimes, a valve may fail to open due to debris or corrosion. Regular maintenance is crucial to avoid such issues. Operators must inspect and test safety valves frequently. This ensures they function correctly when needed. A neglected safety valve can lead to catastrophic failures.

Proper installation also affects performance. Valves must be installed in the right orientation. Misalignment can cause malfunction. Additionally, choosing the appropriate size is vital. An undersized valve won’t handle high pressure. A valve that is too large may not close properly. Understanding these details can enhance a system's safety and efficiency.

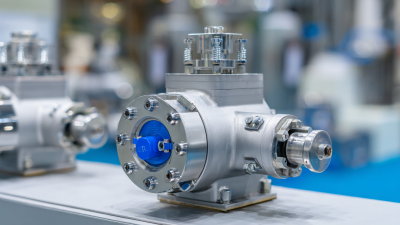

Choosing the right type of safety valve is crucial for optimal performance. Different applications require different features. For instance, pressure relief valves play a key role in steam and gas systems. On the other hand, liquid applications might need valves with specific flow characteristics. Identifying your system’s medium helps narrow down your options.

Consider the operating conditions. High temperatures demand valves that can withstand severe environments. A common mistake is to underestimate pressure fluctuations. This can lead to valve failure. Additionally, think about the size. A mismatched valve can cause inefficiencies. The valve should align with pipe diameter and system requirements.

It's vital to review manufacturer specifications. Not all valves are created equal. Some may not operate well under your specific conditions. Pay attention to installation and maintenance needs as well. Complicated setups can lead to installation errors. Proper training can alleviate some challenges, but reflection on past experiences is key. Sometimes, even small changes can lead to significant improvements.

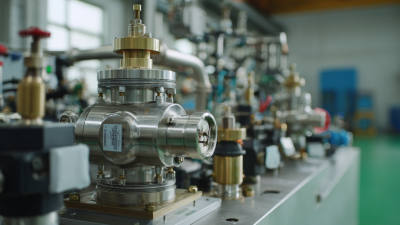

Installing a safety valve is crucial for system reliability. Start by identifying the right location. It should be easily accessible for maintenance. Proper placement ensures effective performance. Choose a valve that fits your system's specific pressure requirements.

When you install, make sure to check the orientation. Safety valves typically require a vertical position. This helps in avoiding any malfunctions. Misalignment can lead to pressure build-up. Pay attention to the piping and connections as well. A leak here can negate the safety features.

Here are some tips: Always use a torque wrench. This avoids over-tightening and potential damage. Consider performing regular inspections to catch issues early. It may be wise to keep a log of maintenance activities. Regular checks can improve long-term performance. Safety should never be an afterthought.

Safety valves are crucial in many systems. They help prevent pressure buildup and potential hazards. However, simply installing them is not enough. Regular maintenance and testing are vital for reliable operation.

Start with visual inspections. Look for any signs of corrosion or wear. Check connections and seals. These parts often experience stress and may need replacement. Each valve should also be tested periodically. Functional tests ensure they open and close correctly. It can be alarming when a valve fails during operation. Scheduled testing can help avoid these moments.

Make it a routine. Set reminders for inspections and tests. Involve your team in this process. Document each maintenance task thoroughly. Reflection is important here. Ask if there are better ways to manage these valves. Regular check-ups can seem tedious, yet they are essential. A small oversight could lead to significant issues down the line.

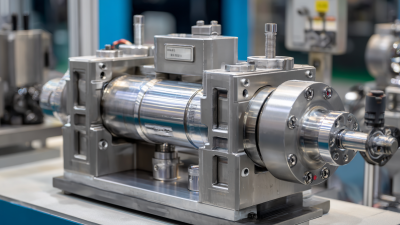

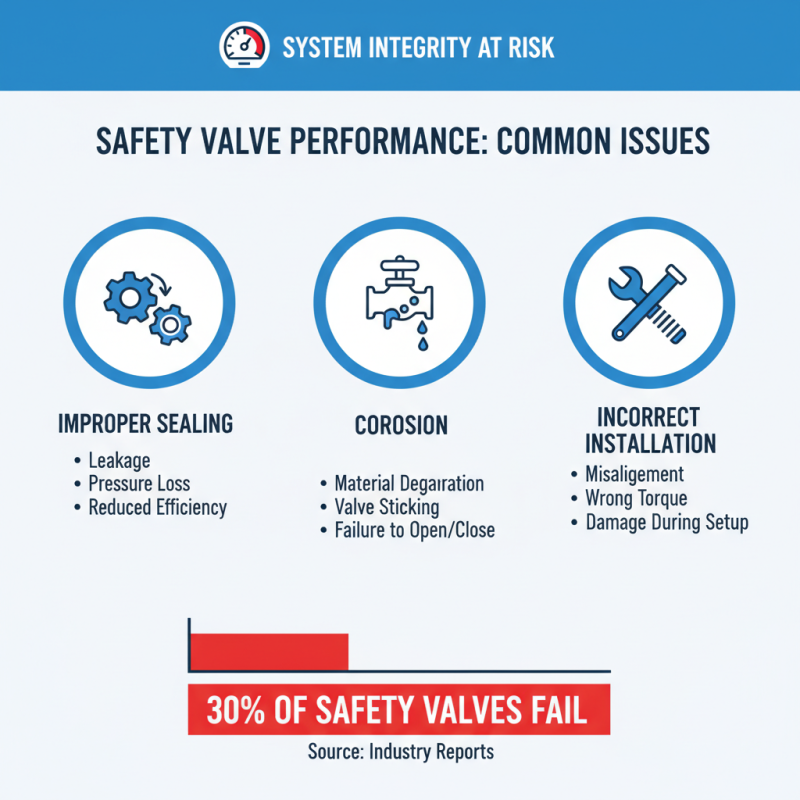

Safety valves are crucial for maintaining system integrity. However, they often face performance issues. Common problems include improper sealing, corrosion, and incorrect installation. According to industry reports, nearly 30% of all safety valves do not perform as expected.

Corrosion is a silent killer. It weakens the valve structure. A study revealed that over 40% of safety valves with significant corrosion fail to seal correctly. This can lead to dangerous overpressure conditions. Regular inspection is essential. Look for signs of wear, especially in harsh environments.

Improper installation is another frequent issue. Misaligned valves can cause leaks. Research indicates that around 25% of safety valve failures stem from installation errors. Ensuring accurate alignment during installation can mitigate this risk. Operators should also consider training to understand best practices. Addressing these issues early can enhance performance and safety significantly.